Our Work

Project Description

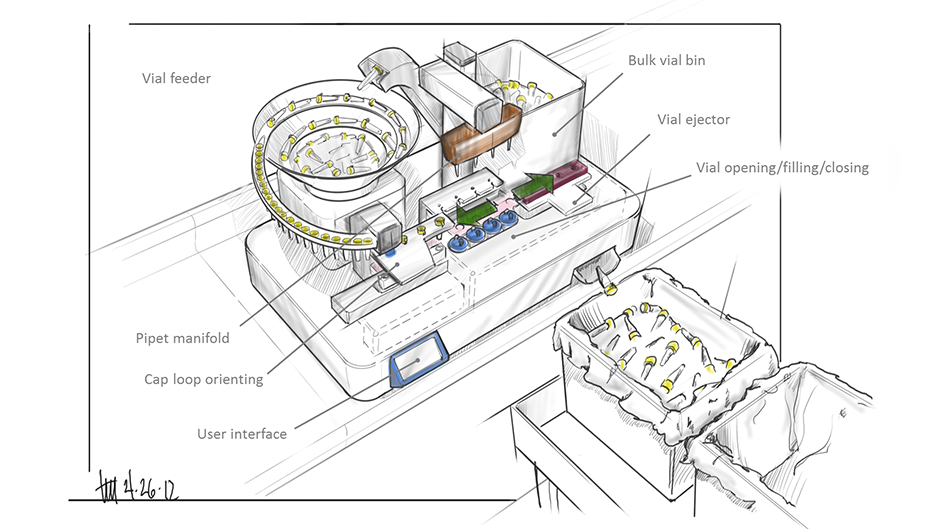

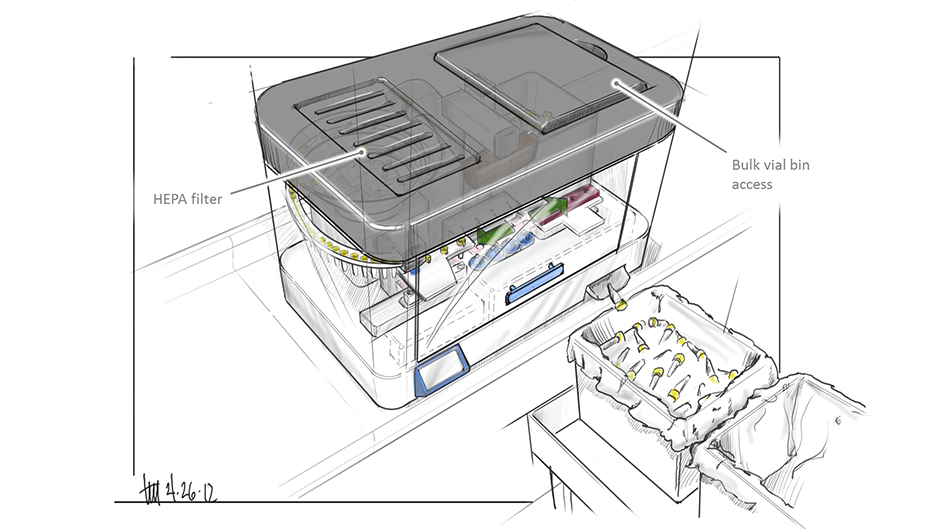

Summary of Work: Our client needed to automate a labor-intensive manual filling process to improve quality, throughput, and reduce labor costs. However, their custom leashed-cap microtubes presented a significant challenge; no off-the-shelf equipment could accommodate this type of tube. Intense Engineering rose to the challenge and developed an automated system to do that and more, with a list of requirements including:

- Throughput of up to 20 tubes/min

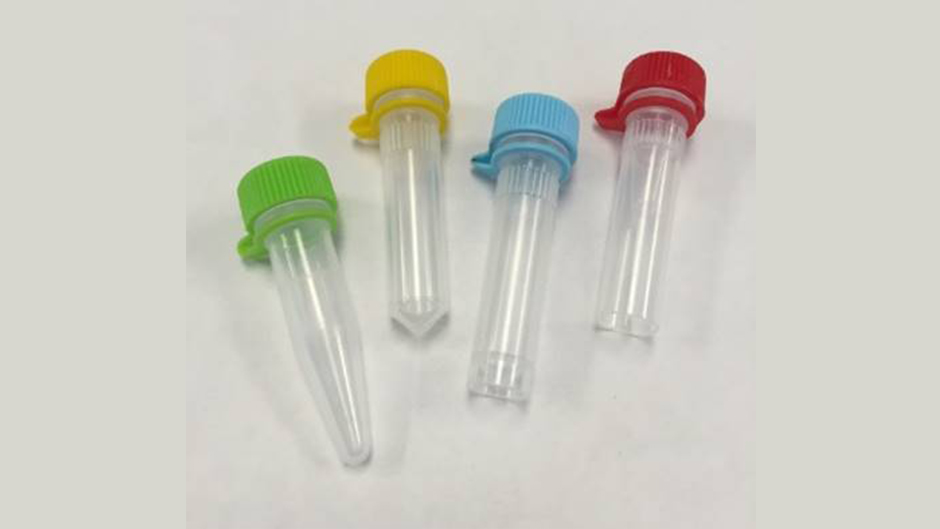

- 4 different 2mL leashed cap microtubes

- 2μL - 2mL fill volumes with 2% CV accuracy/precision

- In-line fill presence inspection

- Water, ethanol, and glycerol based reagents

- Automatic tube feeding system (1,200 tube capacity)

- Easy change over with disposable product contact parts

- Compact (fits on benchtop or inside laminar flow hood)

- Integrated reagent cooling